Nurton Distribution Service Reservoir

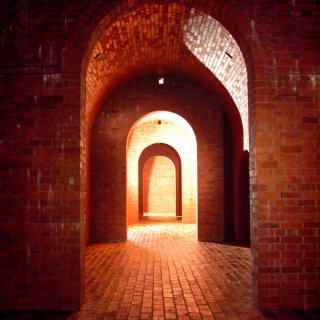

Nurton DSR which was built in 1980 consists of two above ground tanks of 49m diameter covered by a dome concrete roof. They are situated predominantly above ground and are of a circular reinforced concrete construction, with reinforced concrete floors and dome roofs. It is not known whether the roofs are of prestressed, or conventional reinforced concrete construction. The reservoirs consist of single cells each.

In February 2021 an inspection of the North reservoir (both external & internal) was carried out which identified a number of defects. Concrete Repairs Limited (CRL) as one of the reservoir refurbishment framework contractors for Severn Trent was asked to tender for the works and awarded the contract to undertake the repairs and refurbishment in March 2021.

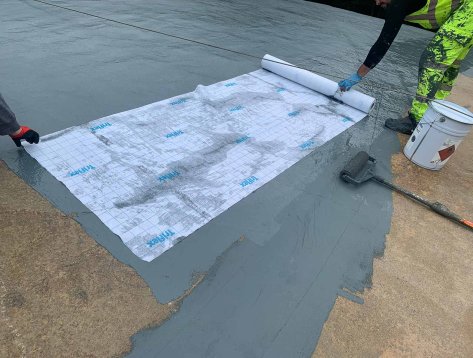

The works were varied as is expected for an asset of this nature. Externally, a complete removal of the existing roof covering, and an application of a new fully bonded coating was required. This was in addition to sundry works such as hatch re-bedding, circumferential sealant joint replacement, sealing of cable entry points and drainage renewal. CRL played a major role in the development and approval of the Triflex MMA specification as the roof covering needed to meet a 20-year design life.

Internally, the works included extensive removal and replacement of wall and floor joint overbanding, access gantry survey and refurbishment, concrete repairs, installation of safety gratings, cleaning, and disinfection. The internal works required a significant large, designed scaffolding to provide access to the entire circumference of the tank, in a particular sequence and programmed to meet the delivery date. With CRL’s tried and trusted supply chain, and a workforce structure that offers flexibility in how we respond to the needs of our clients we were able to respond to the short mobilisation and programme period to successfully deliver a project of this nature.

The works consisted of the following;

-

- Establish site & confined space access system

Internal

- Establish site & confined space access system

-

-

- Install scaffolding access to walls,

- Remove all existing joint overbanding,

- Prepare concrete surfaces & install new overbanding, and

- Clean & chlorinate.

-

External

-

-

- Erect scaffolding access,

- Prepare dome & ring beam surfaces to receive ‘Waterproof/protective’ membrane,

- Clean out horizontal joint between ring beam & reservoir wall,

- Apply Triflex’s ProTect Waterproofing System,

- Remove & replace existing downpipes and install an additional 3 gulley’s & downpipes,

- Install elastomeric sealant in horizontal joint between ring beam & reservoir wall, and

- Water test roof/dome.

-

"I have received very good feedback in terms of overbanding installation from James and Ashleigh, good job. Please keep up the pace and the quality of the work for this last month of works."

Tomas Cruz | Consultant Project Manager | Severn Trent Water - CCS